Improve:

Companion Line OEE Improvement

Improve:

Companion Line OEE Improvement

As part of the Improve phase the project team has looked at data analysed during the Analyse phase of the project. As graphed in the Analyse phase of my blog, in order for the Companion line to meet an our required OEE of 70% then we must improve our line takt time by 0.48 seconds, 3.10 seconds to 2.62 seconds.

From the Analyse phase of the project, the main items affecting this takt time were:

- Assembly machine paper band faults

- Flowrapper crimp torque faults

- Stopcock machine feeder bowl jam faults

- Operator reaction time to faults

- House keeping 5S

1) As the Paper Band faults RCA actions were complete and a supplier complaint was lodged with the supplier of the paper band, the team looked at the best possible way optimise the the performance of the paper band station, along with inconsistent peal torque values, it was also found that the the adhesive coating was not consistent between paper band batches and from line experience, excessive adhesive on paper band leads to adhesive build up on the paper band cutting mechanism leading to failure of the station to operate.

In an effort to address this build up, the project team decided to introduce a maintenance intervention twice per shift, where the Crafts man on duty would clean the cutting blade on the paper band station during operator breaks, therefore removing excessive build up of paper band adhesive.

This action was an interim action to the suppler complaint raised, in order to improve the consistency of the paper band batch received from our supplier.

2) Similar to the paper band station reliability, once the data from the Analyse phase was analysed, it was found that short stops on the Flowrapper caused by crimp torques, were causing significant amounts of downtime that again warranted a maintenance intervention twice per shift, also during the operator breaks. A check sheet to verify the cleaning maintenance on the paper band and Flowrapper crimp stations was put in place.

3) Stopcock machine feeder bowl

There exists a number of snag points on the Stopcock feeder bowl, once a Stopcock becomes snagged on one of these points a short stop downtime interval occurs, starving the Stopcock assembly machine of Stopcocks. After investigation it was noted that this bowl had in fact been designed for a different type of Stopcock and had been modified in house to feed the Companion line Stopcock, every effort had been made to engineer the snag point out of the bowl for the running of the Companion line Stopcock, the decision was take as part of this project to install a Stopcock feeder bowl track low level sensor on the track leading from the feeder bowl to the assembly machine, once this sensor was not made for a predetermined period of time, then a sounder would go off, alerting the operator to a feeder bowl jam. Also as part of this project a proposal has been brought to Senior Management to apply for a capital investment to replace this bowl.

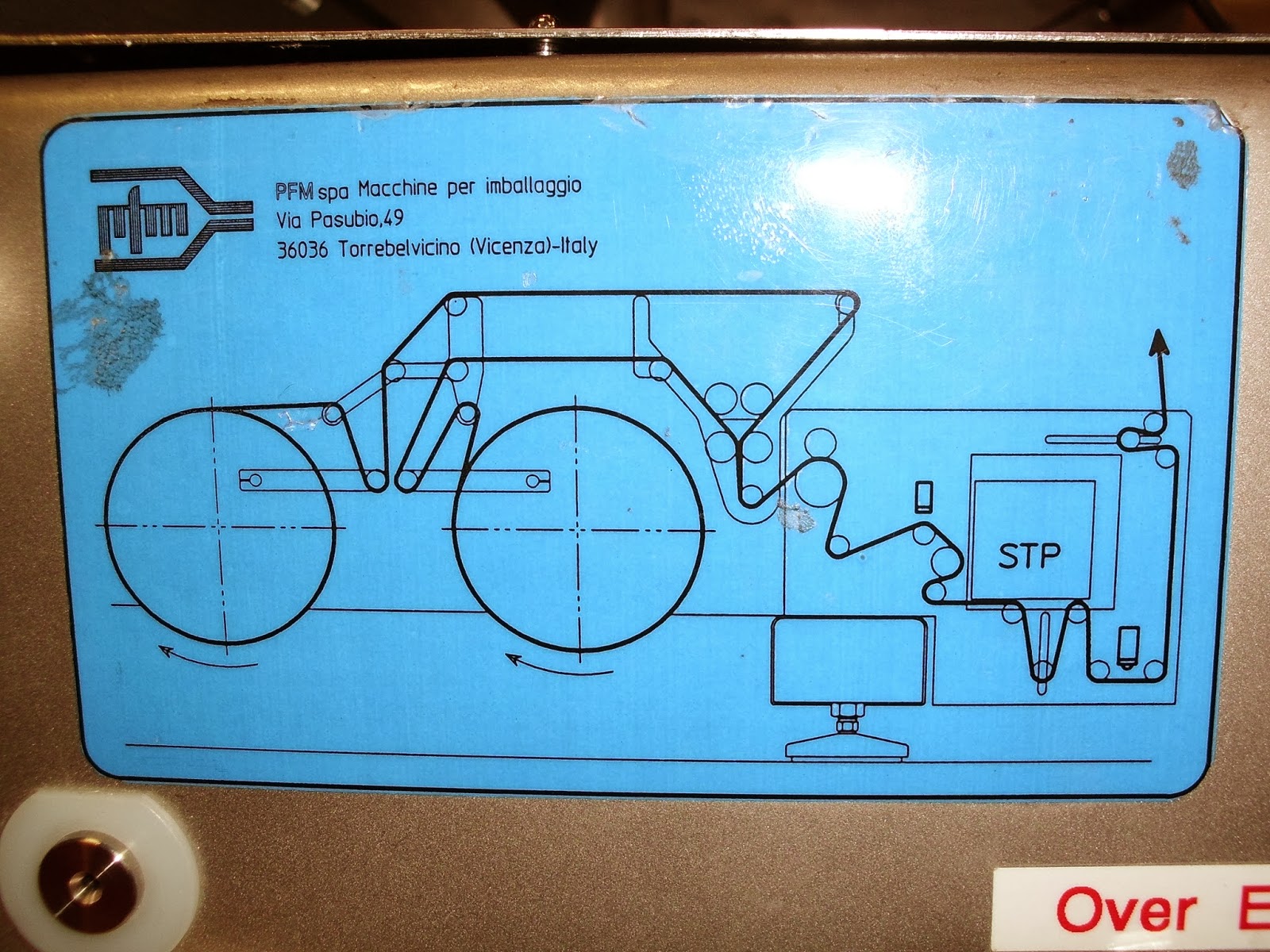

4) Operator reaction times to a machine alarm and also to clear machine alarms was identified as a major contributor to machine down time, in order to assist the operators with their knowledge and training on equipment, machine Job Aids were developed an example of an image taken from the Flowrapper Job Aid can be seen here:

5) Companion Line 5 S;

SECTION

1.0 PURPOSE

To create and maintain an

organised, clean, safe and high-performance Manufacturing Line at the manufacturing facility.

SECTION

2.0 SCOPE

This procedure will

describe the management and control for managing Manufacturing Lines under the

following headings:

- Sort

- Set in order

- Shine

- Standardise

- Sustain

SECTION

3.0 DEFINITIONS AND ABBREVIATIONS

Sort

|

Clearly distinguish

needed items from unneeded items and eliminate the latter

|

Set

in order

|

Keep needed items in the

correct place to allow for easy and immediate retrieval

|

Shine

|

Keep the work area clean

|

Standardise

|

Standardise the first

three S’s

|

Sustain

|

Make a habit of

maintaining established procedures.

|

SECTION

4.0 The 5S process

SORT

Goal is to remove all items

from the Manufacturing Line that are not needed for during production.

5S Red Tag Procedure:

- Identify unnecessary,

unneeded, or misplaced items.

- Fill out the 5S red

tag

- Log the red tagged

item into the 5S

Red Tag Register

- Move the item to the

red tag area

- After a given amount

of time (typically one week), in the Central Red Tag Area, remove the item

as it is no longer necessary.

Examples of red tags

Red Tag

|

Red Tag No.

|

|

Date Tagged

|

|

Office Location

|

|

Item

(s) Description

|

|

|

|

|

|

Quantity

|

|

Reason

for Tagging

|

|

|

SET IN ORDER

Goal is to arrange needed

items in the office.

- Visually organise the Manufacturing Line

·

Draw

boarders to identify work area’s

·

Provide

a “home address” for each bordered area

SHINE

Goal is to remove dirt and

dust from the Manufacturing Line.

- Determine shine targets

- Set a housekeeping

schedule and assign responsibilities.

See below an example of a housekeeping schedule.

5S The Manufacturing

Line Housekeeping : Companion 2013 / 2014

|

|

Nov 13

|

Dec 13

|

Jan 14

|

Feb 14

|

Mar 14

|

Apr 14

|

May 14

|

Jun 14

|

Jul 14

|

Aug 14

|

Sept 14

|

Oct 14

|

Seán

|

|

|

|

|

|

|

|

|

|

|

|

|

Keith

|

|

|

|

|

|

|

|

|

|

|

|

|

Martin

|

|

|

|

|

|

|

|

|

|

|

|

|

Shane

|

|

|

|

|

|

|

|

|

|

|

|

|

Chris

|

|

|

|

|

|

|

|

|

|

|

|

|

STANDARDISE

Goal is to create

consistent way of implementing the tasks performed.

- Notice Boards will have at minimum Plant Goals

- 5S Notice Board content standardised

·

T

Cards , Photo of 5S Mfg area • RADOR Diagram

·

Housekeeping

Rota • Housekeeping Checklist

·

Areas

of Responsibility

SUSTAIN

Goal is to have a

discipline that ensures continued success.

- Create 5S radar chart for summarising results.

5S'd Companion Line Inspection area: